DigitalSignage Glass

Interactive flat panel display glass with anti-reflective & anti-glare treatment

The future of digital signage is defined by glass

DigitalSignage Glass

As a glass expert with a partnership-first approach, AGC produces three types of high quality display glass for digital signage optimised for performance and reliability in your specific environment: anti-reflective Clearsight glass, anti-glare Low Sparkling Touch (LST) glass and base Planibel glass.

The future of digital signage is defined by glass

Digital signage is no longer a novelty; it’s a fundamental part of our modern landscape. From bustling airport terminals and interactive retail kiosks to corporate boardrooms and outdoor advertising, digital displays are the primary medium for communicating dynamic information. As the technology behind the pixels continues to advance, the surface through which we view this content has become equally critical. The glass itself is a key enabling technology, and its properties, particularly antiglare and antireflective treatments, are central to the effectiveness of any display.

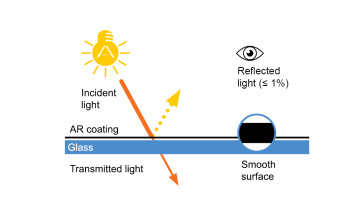

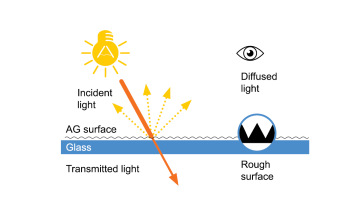

Making glass invisible: anti-reflective vs anti-glare solution

Using displays in a public area, there are multiple external light sources that may reduce readability of the content on the display by creating unwanted light reflection. This is where specialised glass treatments become essential. While often used interchangeably, anti-glare (AG) and anti-reflective (AR) are distinct solutions designed for different challenges.

Clearsight glass with AR coating

LST glass with AG surface

AGC's guarantee of the highest quality

DigitalSignage Glass solutions are premium quality products with proven functionality. They are developed by AGC, a renowned multinational glass manufacturer with a strong tradition and many years of research in the field of display technologies. DigitalSignage Glass products are manufactured by AGC's processing plant in Kryry, Czech Republic, in compliance with the highest quality standards and with respect for the environment.

Key benefits

Areas of Expertise

Our display glass is designed with the user and envirnment in mind. From sunlight-readable screens to e-paper displays, our glass supports applications - whether outdoors or indoors - across transportation, industrial, retail, entertainment, medical and consumer sectors.

Our products are a perfect solution for various types of applications:

Digital advertising & info display panels

Screens that use multimedia content for promotional or informational purposes in high-traffic areas are more dynamic than traditional media. These systems are used in diverse settings, from retail stores to public transportation, to increase visibility and enhance customer experience.

Interactive glass displays

Glass panels that integrate digital content with touch or gesture-based interaction technology. They are used to create dynamic, interactive experiences in various settings, allowing users to touch or interact with the glass to access information, browse products, or participate in presentations.

Touchscreen control panels

Interactive devices that combine a display screen with touch sensors, allowing users to operate a system or device by touching the screen directly instead of using separate buttons or a keyboard. They act as a central interface for controlling a wide range of applications, like industrial automation or smart home systems.

Street furniture & outdoor advertising display panels

Advertisement digital glass panels placed on urban public amenities like bus shelters, kiosks, and newsstands, transforming them into advertising platforms. Their purpose is to reach pedestrians and drivers in high-traffic areas.

Self-service kiosks

Interactive touchscreen terminals that allow customers to perform tasks independently, such as placing an order or making a payment, without the need for direct staff assistance. They are used in various settings like restaurants, grocery stores, and airports to streamline operations and reduce wait times.

Entertainment experience displays

Visual technology glass panels designed to create immersive, interactive, and engaging experiences for audiences in both personal and public settings. These include advanced home theater systems, live venue displays, and interactive displays

E-paper displays

Electronic screen technologies that mimic the look of ordinary ink on paper, making them easy to read and energy-efficient. They create images that reflect ambient light rather than emitting their own, which makes them comfortable to view in direct sunlight and very low-power, as they only consume energy to change the image.

Interested?

You are welcome to proceed

FAQ

With our wide product range and flexible production capabilities, we adapt each delivery schedule to suit the specific requirements of your order. Lead times vary depending on the complexity and customization involved, ensuring every product meets our highest quality standards.

Typical Production Lead Times

Standard Glass Processing: 3–5 weeks from order confirmation

Complex or Specialized Products (e.g. laminated safety glass): 8–12 weeks from order confirmation

We are committed to delivering precision, quality, and reliability—every time. If you need guidance on planning your project timeline, our team is always happy to assist.

Our advanced technologies allow us to handle an exceptionally wide range of glass sizes, tailored to the specific requirements of your project. Exact limits vary depending on the type of processing.

Available Size Range

Minimum dimensions:

Grinding: from 250 × 450 mm

Printing and other specialized finishes: from 300 × 400 mm

Maximum dimensions:

Grinding: up to 1.500 × 2.500 mm

Printing and additional processing: up to 1.500 × 2.300 mm

Whatever your project demands, we’ll help you find the ideal solution — simply get in touch with us.

All our products meet strict European standards (EN) focused on glass products. If you have a specific requirement for impact resistance, e.g. IK code according to EN 62262, we assess compliance by comparing it with the properties defined in EN 12600 and EN 356.

Standards for glass products:

• EN 12150: Standard for thermally toughened (tempered) safety glass.

• EN 12600: Standard specifying the impact resistance of glass (pendulum test), which defines its safety properties when broken. Glass meeting this standard is designated by the classification 2B2 or 1B1 and determines the protection of people against injury and falling through the glazing.

• EN 356: Standard for laminated safety glass, which tests its resistance to vandalism and burglary. Glass meeting this standard is designated by the classification P1A/P2A and higher.

All our products are crafted to order, manufactured precisely according to your technical drawings and specifications. To ensure fast turnaround and maximum flexibility, we maintain a broad selection of base glass in stock, ready for immediate processing.

Our made-to-measure approach guarantees that every piece we deliver meets your exact requirements — with quality, speed, and reliability at the forefront.

Glass thickness and weight are crucial factors in every project, and we approach them individually to ensure the best possible solution for your needs. If your goal is to reduce the overall thickness or weight of your glazing, our experts will proactively propose suitable alternatives.

For instance, we can compare the performance and benefits of monolithic versus laminated glass and recommend the ideal option for your project — always with full respect for safety standards, durability, and visual excellence.

We work with you to find the perfect balance between design, functionality, and technical requirements.

Download

News

AGC processing site in Kryry transformed itself into the manufacturing of glass displays and started the production of DigitalSignage Glass

We are proud to announce that our AGC processing site has successfully launched production of high-performance glass displays designed specifically for digital signage applications. After starting up in 2023, the line is now running at full speed — and the results speak for themselves.

Our commercial team in Kryry offers premium glass solutions featuring advanced anti-reflective and anti-glare treatments, ensuring outstanding visibility even in challenging lighting conditions. Whether installed in retail environments, outdoor kiosks, transportation hubs, or corporate spaces, our displays deliver exceptional clarity, durability, and aesthetic appeal.

This milestone marks an exciting step forward in our mission to offer state-of-the-art glass technologies to our local and international customers. With precision craftsmanship, strict quality control, and innovative surface treatments, our products support the growing global demand for reliable, high-quality digital signage solutions.

Contact us

AGC Processing Teplice a.s. - závod Kryry

Ivana Lokajíčková

Tel: +420 702 066 432

Mail: ivana.lokajickova@agc.com

AGC Processing Teplice a.s., člen AGC Group - závod Kryry

Tovární ul. 439 81 Kryry

Contact form

Leave us your contact details, we will arrange a consultation with you and propose a solution tailored to your needs.